When should I use an extreme bit in horizontal boring?

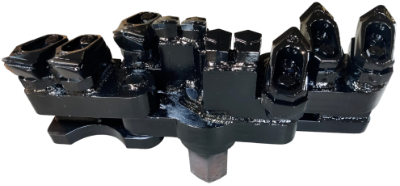

Introduction to Extreme Bits in Horizontal Drilling

Horizontal drilling is a specialized method in the construction and oil and gas industries, allowing for precise underground pathways. The selection of drilling bits, particularly extreme bits, is crucial in navigating challenging geological conditions.

Determining the Need for an Extreme Bit

The decision to use an extreme bit in horizontal boring depends on various factors that ensure the efficiency and success of the drilling process.

- Geological Conditions: Extreme bits are essential in hard rock formations or where the ground is highly abrasive, as they can withstand intense wear and tear.

- Drilling Depth and Distance: In deeper and longer boreholes, extreme bits provide the necessary durability and performance.

- Directional Control: When precise directional drilling is required, extreme bits offer better control and accuracy.

Benefits of Using Extreme Bits in Horizontal Drilling

Extreme bits offer distinct advantages in horizontal boring, making them a preferred choice in specific scenarios.

- Enhanced Durability: Designed for tough conditions, these bits reduce the frequency of replacements and downtime.

- Improved Drilling Efficiency: They cut through hard materials more effectively, speeding up the drilling process.

- Better Directional Control: Extreme bits provide greater precision, essential in complex drilling projects.

Challenges Associated with Extreme Bits

While beneficial, there are also challenges in using extreme bits that must be considered for successful drilling operations.

- Cost Implications: These bits are typically more expensive, impacting the overall budget of the drilling project.

- Specialized Equipment and Skill Requirements: Their use may require additional training and specialized drilling equipment.

In conclusion, the use of extreme bits in horizontal boring is dictated by specific project requirements, geological conditions, and operational considerations. Their benefits in terms of durability and efficiency must be weighed against cost and equipment needs.